The event

On 15th September, we welcomed Eric Pope to talk to our members about the role of leaders in creating a culture of continuous improvement.

Eric started by saying he has been working in US Synthetic for over 30 years. He is the Vice President of Operations and continues to play a key role in its success today. By way of background, US Synthetic is an innovative leader in the energy industry, providing high-performance products and exceptional customer service to help its customers succeed in business. The company has taken its innovative technology and applied it to a variety of new markets, including oil and gas exploration, diamond bearings, coal mining applications, wire drawing dies, and gemstones.

Press play to view the webinar recording or read on for a short summary.

Background

US Synthetic is owned by Champion X and in 2004, they were introduced to Lean concepts. Eric recalled that he was there at the beginning and he was part of the team in bringing these first concepts into the company. He added that they went from a typical manufacturing company to being awarded the Shingo Prize in 2011.

Company Culture

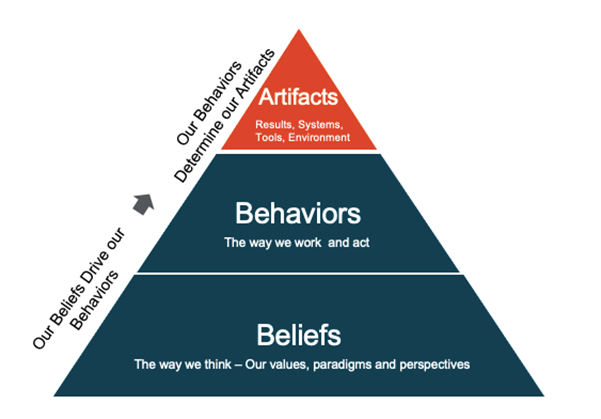

Culture comes from the way we work and the way we behave every single day. He went on to explain that your employees come in to work and over time they see repeated behaviours. As a result, these behaviours ultimately define the environment, the tools, the systems and the results. And so your culture in large part is what you do repeatedly.

Where do your behaviours come from?

How does Culture happen?

One thing leaders need to remember is that leaders create culture through their repeated behaviours. Everything a leader does and says every single day, every interaction with people matters. There are leaders that have a style of work and it is because of their beliefs, they work a certain way and their behaviours are repeated. And those patterns over time start to form team beliefs. It is important to lead with kindness, humility and respect every time.

- Why are we even trying to change? Why do we even care? Why are we going to make this effort? There has to be this compelling reason why we are even going to do this and then that why has to be connected to the strengths of the business. How does a strong business enable our compelling why?

- The second part of the vision is who is our customer and what do they value? How does taking care of the customer every day enable a strong business ?

- We want to be the best in our customers eyes. And that’s an example of a vision that we need to share with every employee. Then there’s also this vision of excellence, how good we can be, how to help them begin to see waste. So expanding people’s vision is important. What we do as leaders then is we got to have a strategic focus of where we’re going and what matters most. The role of a leader is, first of all, to teach people how to see opportunity and then to teach them how to see waste

This is where you use all the lean tools and Lean Principles. They help people to see and expose waste, help them to create flow, help them do value stream maps, and help them to do standard work.

Then, they can start problem solving. They can see their performance relative to the business. They can look at their work systems and see opportunity.

In US Synthetic, Eric said that they get people to do Plan Do Check Act (PDCA). They start doing problem solving. The result of this is new ways of working, new improved tools, new improved methods, and new improved ways of behaving.

As a result of these positive changes and repeated behaviours, the last step is culture. What you’ve actually done is you’ve altered the behaviours of people, you’ve made them believe in a new way or a new tool or a new way of thinking, and they’re going to act in accordance to that. Then, the systems and the environments change and the company’s results are going to change. The leaders role in this is to engage and empower people to be able to see and solve problems.

Next, Eric showed us their daily improvement graph at US Synthetic when they were introduced to the Toyota production system in 2004. In that year, they had 5 improvements a year from shop floor employees. As they used Lean tools in their organisation, their people started to get more engaged. They had more power to be able to see and solve problems. In this year alone, they had over 50,000 improvements from their employees. They were not just ideas. These were actual implemented improvements that they had identified and implemented themselves.

Finally, Eric concluded that it is a leader’s job to make sure people understand that this is a better way of working. A leader’s job is really to activate the creativity and participation of all people in their work and improvement.

At the end of Eric’s presentation, we had a Q & A session with our members:

- What do you do when everyone buys in to Continuous Improvement (CI) but one person doesn’t want change?

- How do you convince leadership that only see cost with talking of CI transformation?

- How do you reconcile a CI culture with looking for opportunities that could be a game changer?

- How do you manage to sustain employee development when restrictions are placed on time to learn and just restrictions?

- How do you create a sense of urgency? So typically what can happen is not now we’re too busy or we’ll do Lean in three months’ time?

This blog post was written by Trish Ferguson, Steering Committee Member of the Dublin Lean Network.

If you would like to receive the PowerPoint presentation of Eric’s talk, please register to join the Network.